12 June 2020

Multifiber push-on (MPO) connectors are becoming more and more popular because of their many advantages for high-speed network operators, owners and installation companies. They are used to connect the fastest links that deliver the most sensitive services and data to customers, enable high-speed interconnects and create redundancy. More and more, telcos are reconfiguring their central offices into data centers (CORDs) and deploying MPO cables with 12 or, increasingly, 24 fibers. In fact, MPOs are quickly emerging as the connectors of choice.

However, since the main source of loss in links is connector related, the failure to properly test and maintain MPO connectors puts the entire network at risk. In fact, without proper validation, CORD operators may end up having to pull the plug on critical lines for troubleshooting.

So, how can you ensure peak MPO performance? It all starts with testing. Let’s take a closer look at the three essential tests to ensure the quality of your link: polarity-type validation, continuity confirmation and connector inspection.

Testing polarity

Polarity simply refers to the way the fibers are arranged inside the cable. During installation, MPO connectors must be properly aligned and mated, which is not as simple as it sounds. Ensuring accurate polarity for MPO fiber array cables is a big deal and can be complicated, due to multiple polarity schemes available for these connectors and polarity flipping during connecting and installation.

Three different polarity types, corresponding to different cable structures, are used with MPO cables. Validating these helps you confirm their type, ensures that signals are traveling in the correct path and connections between the transmitting and receiving end are intact.

In testing polarity, your main goal is to make sure the right transmitter (TX) is sending signals to the right receiver (RX). To accurately send and receive data, MPO connectors must be properly aligned and mated. Bad coupling will impede signal transmission, as the signal could be sent in the wrong direction.

Undiagnosed polarity issues increase CAPEX and work for technicians (i.e., OPEX). Technicians may unnecessarily rip and replace expensive MPO patch cords, believing they are faulty, when in fact they simply did not have the expected polarity type. If polarity issues are not corrected before turn-up, then trying to pinpoint which cable connections have polarity problems after they have been installed becomes a frustrating and tedious guessing game.

Testing continuity

Confirming the continuity of a link ensures that there is no break and that light travels properly all the way to the end of the link. It’s a quick validation test that, when done during installation, can save a lot of potential troubleshooting later.

Testing connector cleanliness

Considering that 80% of network problems are due to dirty connectors, and the No. 1 cause of network failure is contaminated connectors1, it goes without saying that inspection and cleaning are critical.

With multifiber push-on connectors, inspecting and cleaning is particularly important because each port represents a potential point of failure. Additional fibers create more surfaces, which means there is a higher risk of contamination and failure. Bad connectors are a significant cause of loss, and the impact is ever greater for MPO links, where a single dirty or damaged connector can affect as many as 12 or 24 fibers.

How to clean MPOs

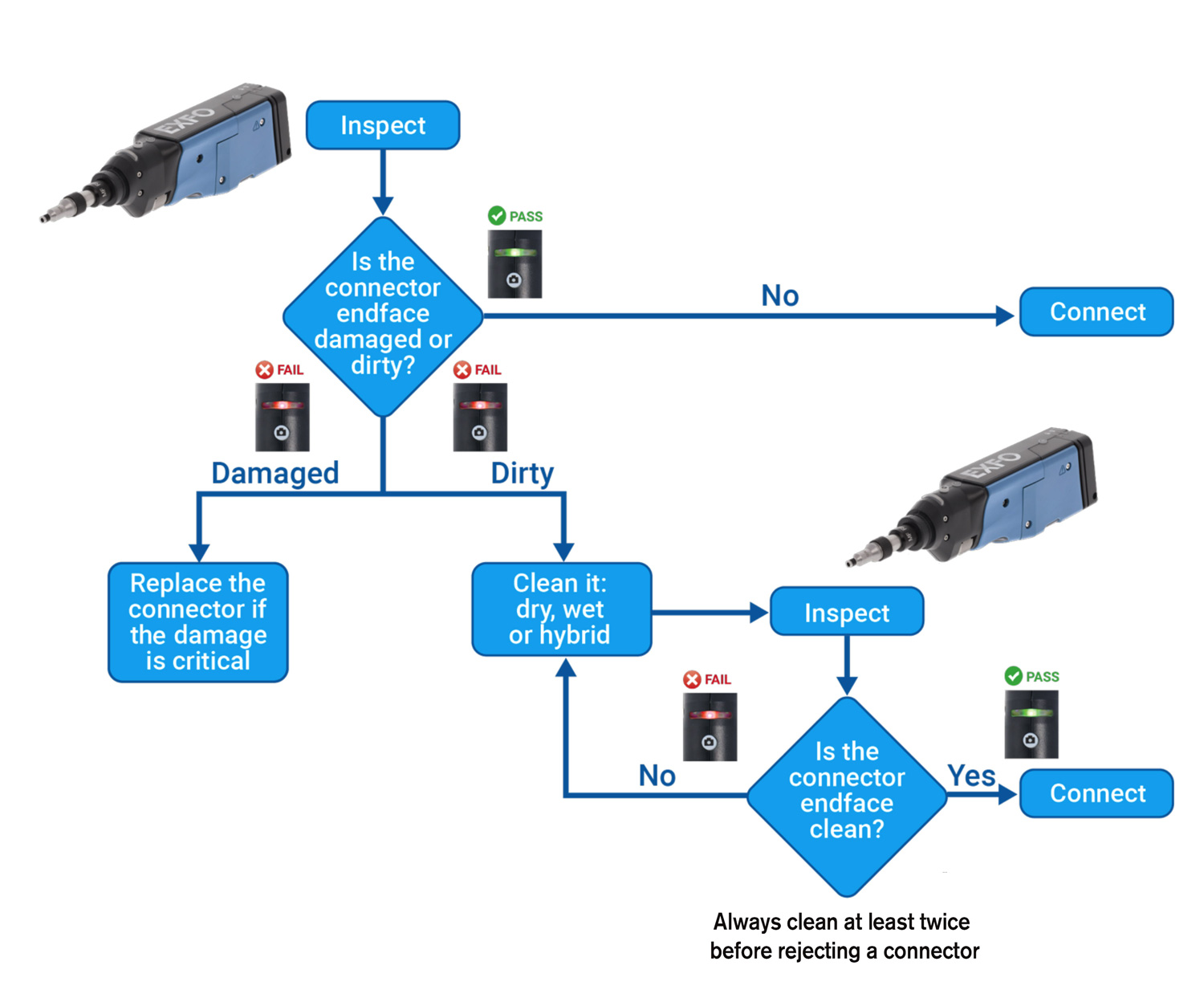

Inspect, clean, reinspect.

1. Inspect

Always inspect the connectors first. You don’t need to clean a connector if it’s already clean, as cleaning it might make it dirty. This is especially true for MPO connectors, which are highly sensitive. For example, for an MPO-24, dirt from the first row could potentially migrate to the second row while cleaning.

Make sure to inspect both mating connectors, as residue from a dirty connector will transfer to a perfectly clean connector once they mate.

2. Clean

If the connector is dirty, first try the dry method.

If the dry method fails to remove the dirt, try the hybrid cleaning method, which involves using a solvent.

3. Reinspect

Always dry your connector after using wet cleaning tools and always reinspect the connector.

Choosing high-performance tools for easy inspection

Given the popularity of MPOs, it’s important to know how to take full advantage of these powerful cables. Choosing the right testing tools and making sure your cables have passed the three essential MPO tests—polarity, continuity and inspection—are critical to turning up and maintaining efficient links. What’s more, to guarantee that your network is future proof and can meet the ever-increasing demand for bandwidth, it is crucial to ensure connectors are in good condition.

The tools and solutions on the market today are better than ever, allowing you to:

• Inspect single and multifiber cables using the same tool by simply switching the adapter

• Take advantage of a slim design to easily access recessed connectors and dense panel settings

• Get an automated analysis of all fibers for multifiber cables and obtain a clear pass or fail result according to your test configuration

One solution, three essential MPO tests

EXFO’s ConnectorMax MPO Link Test Solution is an automated, all-in-one solution to validate polarity, continuity and connector cleanliness of MPO fiber optic links of any type, including MPO 12 and MPO 24 singlemode or multimode cables as well as APC or UPC and male or female connectors.

The ConnectorMax MPO Link Test Solution pairs a light source at one end of the cable with a fiber inspection probe for analysis at the other end—a first in the industry. The solution brings together the ConnectorMax Multifiber Source with the ConnectorMax Fiber Inspection Probe to deliver a quick and easy-to-use solution that helps operators test and turn up networks right the first time—making deployments faster, more efficient and cost effective.

Results are loaded in ConnectorMax Analysis Software, an app for mobile devices that provides clear pass/fail status and reporting functions, making it easy for technicians to perform and view the results of all three of these tests on the spot.